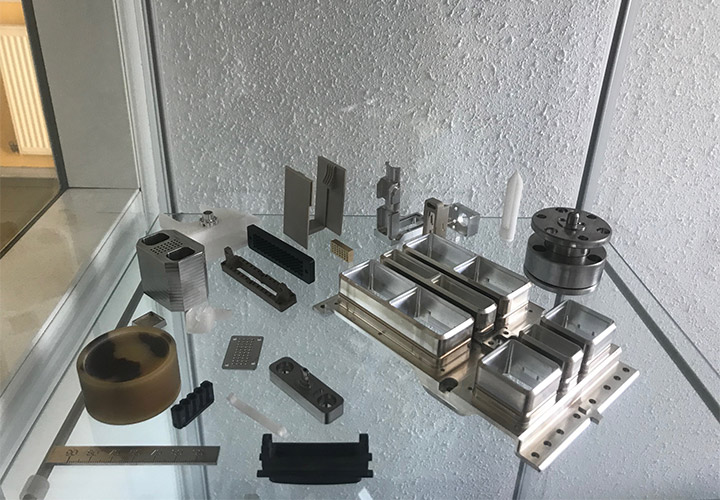

After its creation in 2014 as an engineering consultant, JY’NOVE decides in 2019 to set up its own production workshop in order to respond to the increasing demand of its customers. Equipped only with the latest-generation technology of 5-axis machining centers, this new production site enables the company to pursue its development by offering a high level of technicality in multi-axis machining of complex parts. Technicality and Reactivity is our motto to support you in the development of your new projects.

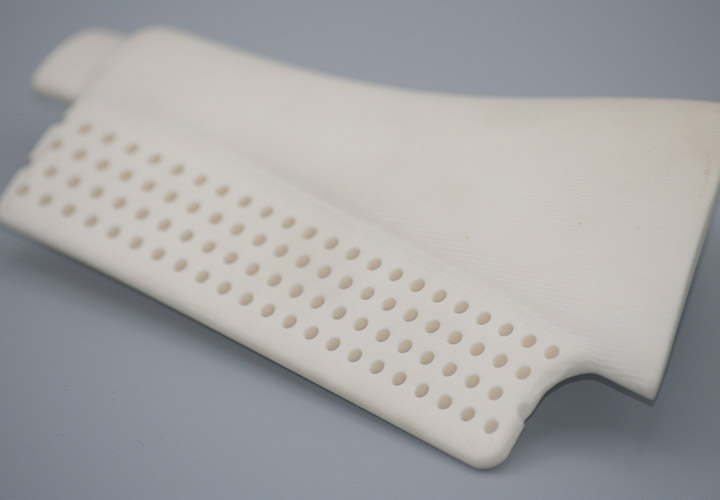

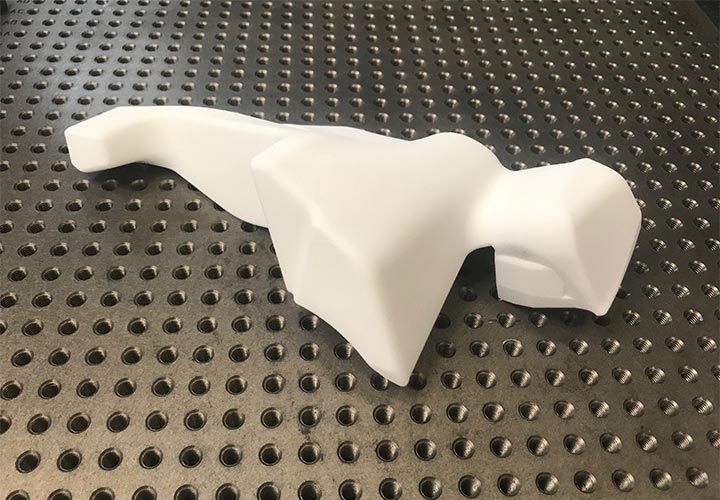

We have a recognized know-how in complex milling and turning machining of the following materials: inconel, ceramics, carbon, titanium, aluminium alloys, glass fiber and rare plastics.The parts we produce range in size from 2mm³ to 700mm³. The requested lead times are sometimes very short, not exceeding 3 days.

Our machined parts are highly technical, with non-straight shapes (requiring continuous 5 axis machining), deep drilling (40 x Ø), with tolerances up to a hundredth of a millimeter.

Ask for a free quote for all your needs in multi-axis machining by sending us your drawing via the tab “Ask for a quote” on our website and we will get back to you in the next days.

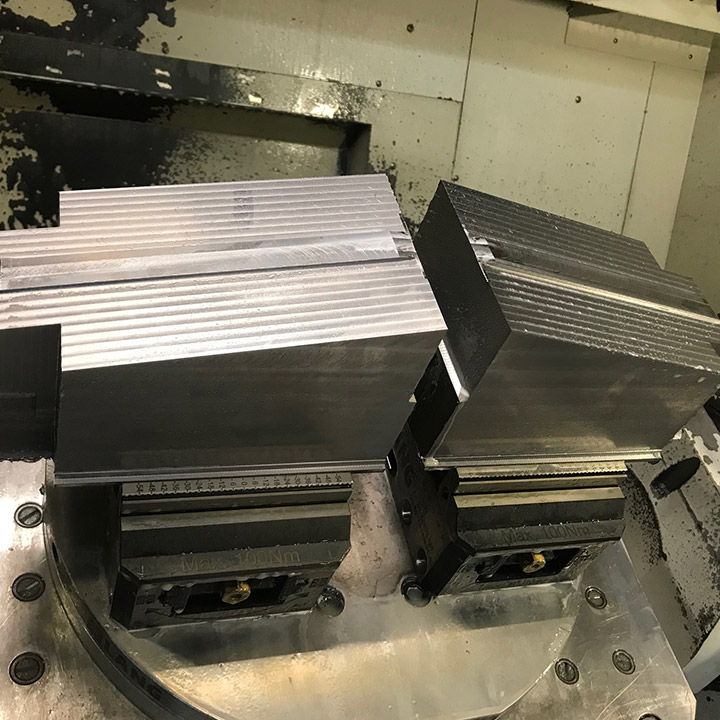

Machine Park

The guarantee of quality of our products is high-tech equipment. Through state-of-the-art CNC machines from Japan, up to control CNC coordinate measuring machine from ZEISS Germany.

- 5 Axis Milling and Turning

- 5 Axis EDM

- 5 Axis CMM

We use sophisticated CAD / CAM softwares, such as Solidworks and GibbsCam

We prescribe solutions for your machined parts through :

- Choice of material for a given application

- Design optimization to facilitate implementation

- 5 AXIS MECTRON MTV - T212: HSM machining center (80mm diameter table)

- 5 AXIS MECTRON MTV - T311 : high speed precision machining (200mm diameter table)

- 5 AXIS OKK VCX 350L : HSC machining center (milling and turning, 350mm diameter table)

- 5 AXIS OKK VP600: HSC machining center (500mm diameter table)

- ZEISS CONTURA CMM: coordinate measuring machine ±0.0012mm, using Calypso, stroke: 700mm*1000mm*600mm

- Polishing station with central vacuum system

- 5 AXIS EDM : CHARMILLES

- 3D Printer: « Coming soon »